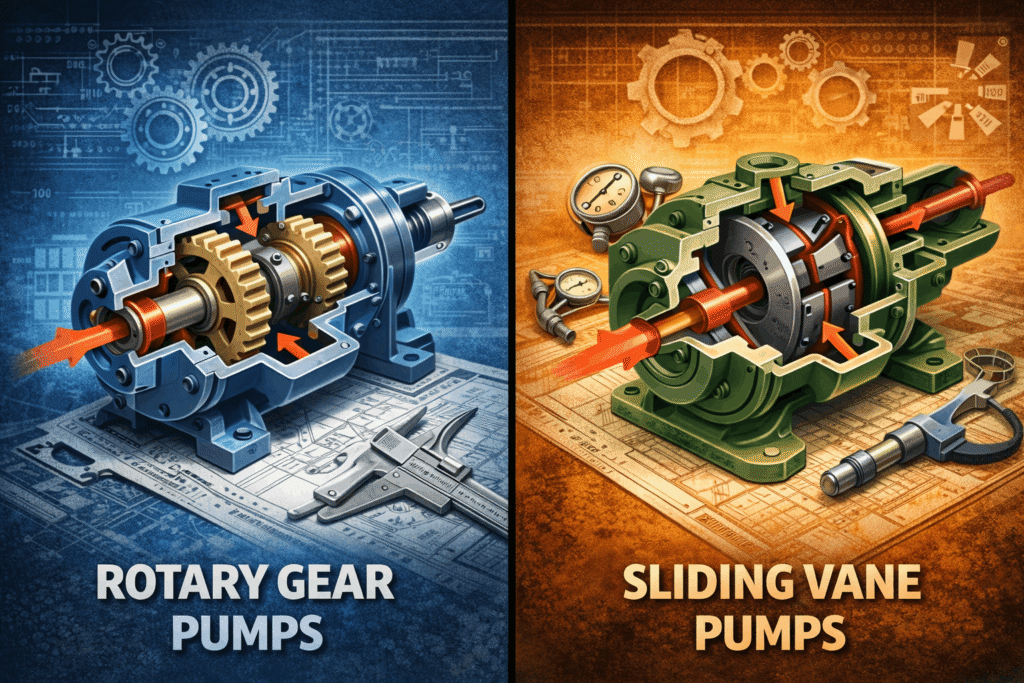

Rotary positive displacement pumps play a critical role in industrial systems that depend on predictable flow, repeatable dosing, and controlled pressure. Among the most widely specified designs are rotary gear pumps and sliding vane pumps.

Both technologies handle viscous fluids, deliver steady discharge, and support volumetric accuracy. However, their internal mechanics differ significantly, influencing how they perform under changing viscosity, pressure, wear, and maintenance conditions.

This comparative guide examines how rotary gear pumps and sliding vane pumps work, where each design performs best, and what constraints engineers must consider when selecting between them.

How Rotary Gear Pumps Operate

Rotary gear pumps use two meshing gears housed within a close-tolerance casing. As the gears rotate, fluid fills the cavities between the gear teeth and the pump housing. The fluid is carried around the outer perimeter and displaced at the outlet as the gears re-mesh.

Key Operating Characteristics

- Steady, near-pulseless flow

- High volumetric consistency

- Strong performance with viscous, lubricating fluids

- Minimal internal slip at moderate pressures

- Defined clearances that support accurate metering

The rigid geometry of a gear pump makes flow behaviour highly predictable when operating conditions remain stable.

Where Rotary Gear Pumps Perform Best

Rotary gear pumps are well-suited to continuous, steady-state processes involving clean, viscous fluids.

Common application strengths include:

- High discharge pressure capability

- Consistent output across long-run cycles

- Compact footprint for skid-mounted systems

- Wide operating temperature range

- Low pulsation for precision processes

These attributes make rotary gear pumps a strong fit for chemical processing, lubrication systems, polymers, resins, adhesives, and metered transfer duties.

Constraints of Rotary Gear Pumps

The exact tight tolerances that support accuracy also define the pump’s limits.

Primary constraints include:

- Progressive gear wear increases internal leakage

- Poor tolerance for abrasive solids

- Reduced efficiency with low-viscosity fluid

- Sensitivity to thermal expansion

- Immediate damage if run dry

Performance degradation typically stems from clearance disruption rather than mechanical failure.

How Sliding Vane Pumps Operate

Sliding vane pumps use a rotor with radial slots that hold vanes. As the rotor turns, centrifugal force pushes the vanes outward, keeping them in contact with the pump casing. This creates expanding chambers at the inlet and contracting chambers at discharge.

Key Operating Characteristics

- Self-adjusting vane movement

- High suction and self-priming capability

- Stable flow despite internal wear

- Better efficiency with low-viscosity fluids

- Low shear handling for sensitive liquids

Because vanes continuously compensate for wear, internal clearances remain effective over time.

Where Sliding Vane Pumps Excel

Sliding vane pumps perform well in systems with variable operating conditions or thin liquids.

Notable advantages include:

- Strong suction under challenging inlet conditions

- Effective handling of low-viscosity fluids

- Tolerance for light solids in suspension

- Smooth, low-pulsation discharge

- Adaptability to changing pressures and flow demands

These qualities make sliding vane pumps suitable for fuel transfer, solvent handling, chemical distribution, and industrial fluid circulation systems.

Constraints of Sliding Vane Pumps

The moving vanes introduce additional wear considerations.

Primary constraints include:

- Accelerated vane wear in abrasive services

- Shortened service life with incorrect vane material selection

- Increased casing wear during dry-run events

- Higher routine maintenance in certain applications

Proper material selection is critical to balancing performance and longevity.

Rotary Gear Pumps vs. Sliding Vane Pumps: A Direct Comparison

| Engineering Consideration | Rotary Gear Pump | Sliding Vane Pump |

| Fluid viscosity range | Best with medium to high viscosity | Performs well across a wide viscosity range |

| Discharge pressure | High-pressure capability | Moderate pressure capability |

| Suction performance | Good | Excellent |

| Wear compensation | Fixed clearances | Self-adjusting vanes |

| Solids tolerance | Very limited | Limited but more forgiving |

| Flow stability over time | Degrades with wear | Remains stable with wear |

| Dry-run tolerance | None | Limited, still risky |

| Maintenance pattern | Lower frequency, higher sensitivity | More frequent, more adaptable |

Selecting the Right Pump Based on Process Demands

From an engineering perspective, the choice often comes down to operating conditions rather than flow rate alone.

Rotary gear pumps align best with applications that require:

- High pressure

- Viscous, lubricating fluids

- Tight volumetric accuracy

- Minimal pulsation in controlled systems

Sliding vane pumps align best with applications that require:

- Strong suction and self-priming

- Efficient handling of low-viscosity fluids

- Flow stability as components wear

- Operational flexibility under changing conditions

Understanding these distinctions reduces premature wear, energy inefficiency, and unplanned downtime.

Making Confident Pump Decisions Through Engineering Clarity

Both rotary gear pumps and sliding vane pumps deliver reliable, controlled flow when matched correctly to their duty. Their internal mechanisms directly influence efficiency, maintenance behaviour, and long-term stability.

Evaluating viscosity range, suction conditions, solids content, temperature variation, and maintenance expectations helps engineers specify the right pump from the outset. Working with experienced distributors ensures these variables are addressed before installation.