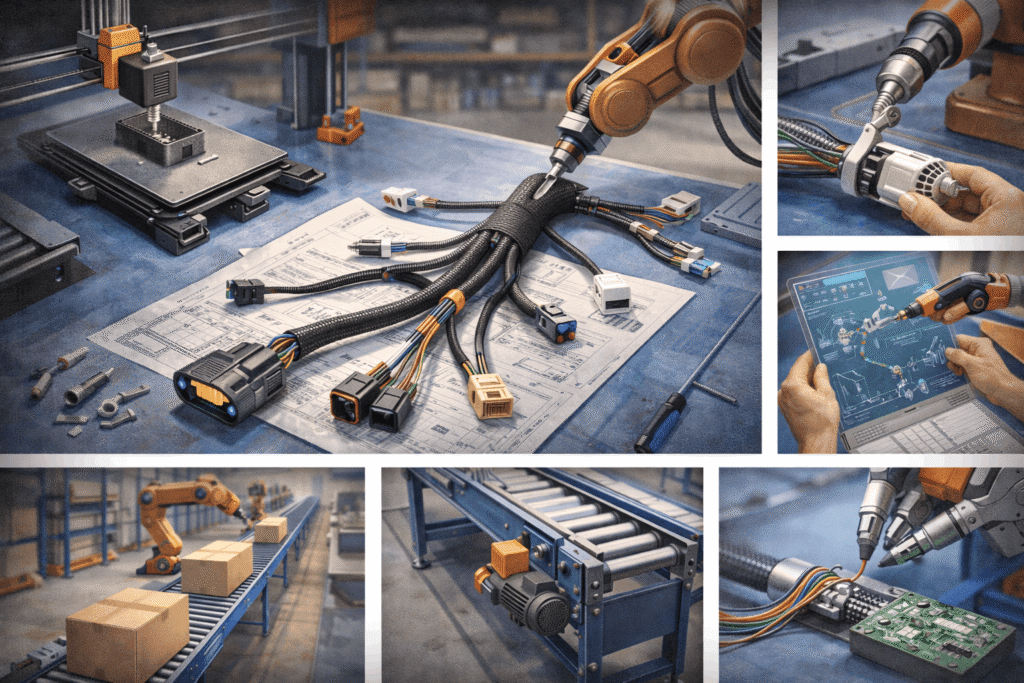

Complex products continue to pack more functionality into smaller form factors. As systems become increasingly connected, wiring harness design faces increasing pressure to deliver reliability, efficiency, and manufacturability at scale. When harness layouts fall short of these requirements, production delays, rework, and long-term failures often follow.

These challenges matter because wire harness assemblies are the backbone of electronic systems across many essential industries. Forward-looking design practices now help reduce risk while supporting performance, compliance, and scalability.

1. High-Density Harness Design for Space-Constrained Systems

Shrinking product footprints demand wiring solutions that deliver more connections in less space. High-density harness design optimizes conductor routing, connector selection, and shielding strategies.

Key design considerations include:

- Compact connector formats that support higher pin counts

- Optimized wire routing to reduce bend stress and interference

- Integration with printed circuit board assembly (PCBA) layouts and SMT surface mount technology

- Improved strain relief to protect conductors over time

These approaches support multi-conductor, RF coaxial, and battery cable assemblies in the USA that must meet strict space and performance constraints.

2. Design for Manufacturability (DFM) in Harness Engineering

Design for manufacturability plays an increasingly important role in the outcomes of wire harness assembly production. Early alignment between engineering and production teams helps reduce complexity before assembly begins.

Effective DFM practices include:

- Standardized wire lengths and termination methods

- Connector choices that simplify crimping and inspection

- Harness layouts that reduce manual handling steps

- Clear documentation that supports repeatable builds

When DFM principles guide harness engineering, cable and wire harness assemblies move through production with fewer delays and lower risk. This approach also supports integration with through-hole PCB assembly technology and electro-mechanical assembly services.

3. Modular and Scalable Harness Architectures

Product lines rarely remain static. Modular harness architectures allow systems to scale without redesigning entire assemblies. This flexibility supports faster updates and easier serviceability.

Modular design strategies often involve:

- Sub-harnesses that connect through standardized interfaces

- Scalable layouts that accommodate optional features

- Simplified upgrades for control panels and box build assembly manufacturers in the USA

- Reduced impact when design changes occur

Modularity benefits wire harness applications across industrial automation, automotive platforms, and medical cable assembly, where lifecycle changes are common.

4. Digital Design Tools and Data-Driven Harness Validation

Digital tools now support more accurate cable harness assembly design and validation before physical assembly begins. Data-driven workflows help identify risks early and improve overall quality.

Modern digital practices include:

- 3D harness modeling integrated with mechanical assemblies

- Electrical simulations that validate signal integrity

- Digital documentation that aligns with supply chain management systems

- Traceability tools that support regulated environments

These tools strengthen collaboration between engineering services and production teams. This helps improve outcomes for military assemblies, medical devices, and aerospace programs.

5. Reliability-Focused Design for Long-Lifecycle Applications

Many industries demand wiring harnesses that perform reliably over extended lifecycles. Reliability-focused design addresses environmental stress, vibration, and repeated use.

Design elements that improve long-term performance include:

- Material selection matched to temperature and chemical exposure

- Redundant conductors in critical circuits

- Robust termination methods for wire jumper assemblies and IDC flat ribbon cable assemblies

- Testing protocols aligned with application requirements

Reliability-driven design supports long-service applications across aerospace and defense, industrial automation, and medical equipment, where downtime carries significant consequences.

How These Advances Influence Wiring Harness Assembly Outcomes

Forward-looking advances in harness assembly design influence more than layout efficiency. They shape production consistency, system reliability, and long-term maintainability. High-density layouts support compact systems. DFM principles reduce manufacturing friction. Modular architectures improve scalability. Digital validation strengthens quality control. Reliability-focused design protects long-lifecycle investments.

Together, these advances enable wiring harness assemblies to integrate seamlessly with PCBA and custom cable assemblies, as well as with wire harness manufacturers.