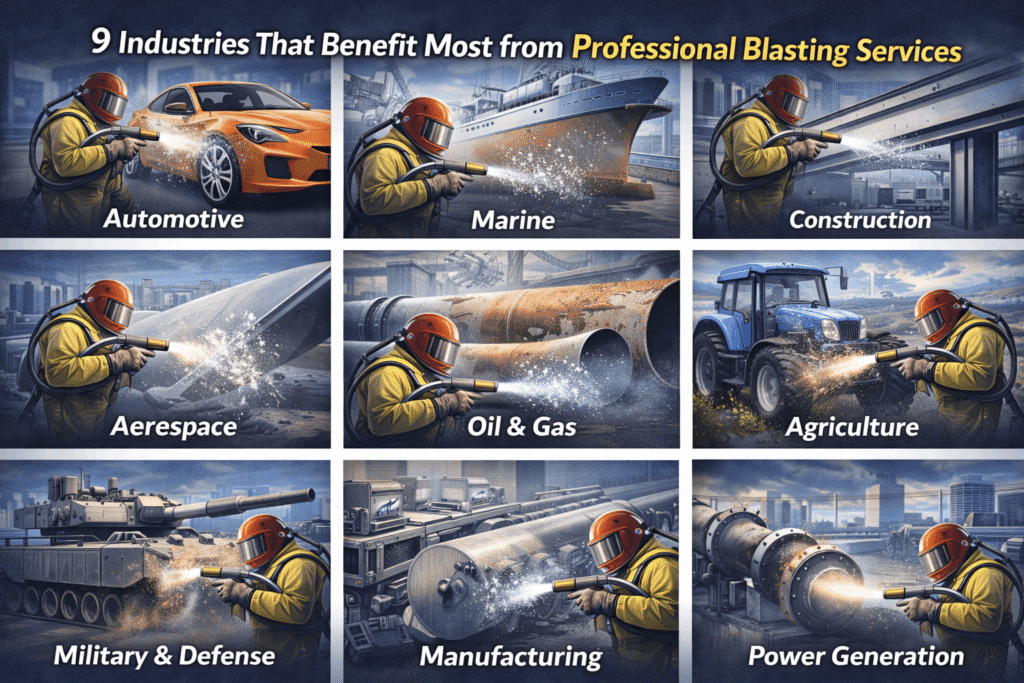

Professional blasting services play a critical role in industrial surface preparation across Ontario. From corrosion control to coating performance, blasting ensures metal and concrete substrates are properly cleaned, profiled, and conditioned before finishing, repair, or return to service. Below is a clear, industry-focused list of sectors that rely most heavily on professional blasting—including sandblasting services in key Ontario regions—to protect assets, extend service life, and reduce long-term maintenance costs.

1. Manufacturing and Metal Fabrication Facilities

Manufacturing and fabrication environments depend on professional blasting services to prepare raw materials and fabricated components for coating and assembly. Incoming steel often carries mill scale, oxidation, welding residue, oils, and shop contaminants that interfere with coating adhesion.

Blasting provides:

- Uniform surface cleanliness across complex geometries

- Consistent anchor profiles for powder coatings and industrial finishes

- Reduced rework and improved coating repeatability

Facilities in London, Ontario, that use sandblasting services often integrate blasting directly into production workflows to support quality control and specification compliance.

2. Construction and Structural Steel Projects

Structural steel used in commercial, industrial, and institutional construction must withstand long-term exposure to moisture, temperature fluctuations, and airborne pollutants. Beams, columns, stair systems, platforms, and supports require proper surface preparation before coating.

Professional blasting services:

- Remove mill scale and early-stage corrosion

- Create uniform surface profiles for high-performance coatings

- Reduce on-site touch-ups and coating failures

Sandblasting services in Windsor, Ontario, are commonly used to prepare structural steel before delivery to job sites.

3. Municipal and Public Infrastructure Assets

Municipal infrastructure operates under some of the harshest environmental conditions. Bridges, railings, light poles, transit shelters, and public works equipment are constantly exposed to road salts, moisture, UV radiation, and pollution.

Blasting services support:

- Rehabilitation of aging infrastructure

- Removal of failing coatings and corrosion

- Cost-effective asset life extension

Blasting companies in Ontario are frequently engaged in long-term municipal maintenance and refurbishment programs.

4. Oil, Gas, and Energy Sector Facilities

Energy-sector assets operate under extreme conditions, including temperature variations, chemical exposure, vibration, and continuous operation. Piping systems, pressure vessels, skids, enclosures, and access platforms require precise surface preparation.

Professional blasting services are essential for:

- Removing corrosion and degraded coatings

- Preparing surfaces for advanced protective systems

- Supporting coating performance under thermal and chemical stress

Across Ontario, blasting is a foundational step in maintaining the reliability of energy infrastructure.

5. Mining Operations and Heavy Equipment

Mining environments expose equipment and structures to abrasion, impact, moisture, and corrosive by-products. Crushers, hoppers, conveyors, chutes, frames, and heavy equipment and machinery experience accelerated wear.

Sandblasting services in Sudbury are widely used to:

- Strip worn coatings

- Remove embedded corrosion products

- Prepare surfaces for heavy-duty protective coatings

Blasting supports longer equipment life and reduces replacement frequency in high-wear mining applications.

6. Marine and Waterfront Facilities

Marine and waterfront assets are under constant pressure from moisture, salt exposure, and temperature cycling. Docks, piers, ladders, handrails, supports, and marine equipment degrade rapidly without proper surface preparation.

Blasting services help by:

- Removing salt residues and corrosion products

- Restoring surfaces for marine-grade coatings

- Improving resistance to moisture and chloride penetration

Waterfront facilities across Ontario rely on professional blasting to maintain structural safety and durability.

7. Food Processing and Pharmaceutical Facilities

Food processing and pharmaceutical environments require strict surface cleanliness and coating integrity. Equipment frames, conveyors, racks, and processing lines must remain free from corrosion and flaking coatings.

Controlled blasting services are used to:

- Remove degraded coatings and residues

- Prepare steel and stainless steel surfaces without damage

- Support hygiene, sanitation, and regulatory compliance

Sandblasting services in Barrie, Ontario, are often included in scheduled maintenance programs for these regulated environments.

8. Agricultural and Farming Equipment

Agricultural equipment operates in corrosive environments involving soil, fertilizers, moisture, and seasonal temperature changes. Trailers, implements, storage systems, and handling equipment experience accelerated coating breakdown.

Professional blasting services allow:

- Refurbishment instead of full replacement

- Removal of rust and deteriorated coatings

- Improved coating adhesion and durability

Blasting helps reduce downtime during critical operating seasons.

9. Transportation, Utilities, and Asset Refurbishment Programs

Transportation fleets, utilities, and power distribution systems rely on blasting services to maintain trailers, racks, enclosures, supports, and substation structures exposed to environmental stress.

Blasting plays a central role in:

- Asset refurbishment and recovery programs

- Accurate inspection and repair after coating removal

- Sustainable asset management and reduced material waste

Clean, stripped surfaces enable reliable recoating and long-term protection.

Why Professional Blasting Services Matter Across Industries

Across Ontario’s industrial landscape, professional blasting services remain one of the most effective methods for surface preparation. From manufacturing and construction to mining, infrastructure, energy, food processing, and agriculture, proper blasting directly impacts coating performance, corrosion resistance, and asset longevity.

Blasting ensures surfaces are not just clean but properly prepared to perform under real-world operating conditions, supporting safer operations, longer service life, and reduced lifecycle costs.