Touch interface decisions play a critical role in flight-critical display systems, where precision, reliability, and predictable behavior are non-negotiable. Engineers and OEMs must evaluate how different touchscreen technologies respond under aviation-specific constraints, including vibration, environmental exposure, and long operational lifecycles.

Within aerospace programs, display design services often involve early-stage assessment of input technologies to reduce integration risk and support certification. Understanding how capacitive and infrared touchscreens differ in structure and performance helps inform safer, more resilient interface design decisions.

Why Touchscreen Choice Matters in Flight-Critical Systems

Touchscreens used in flight-critical systems support functions that require accuracy, reliability, and predictable response to maintain operational safety. Display input errors cannot introduce ambiguity or delay. In these environments, touchscreen technology must perform consistently under vibration, altitude changes, temperature variation, and extended service lifecycles.

Choosing between capacitive and infrared touchscreens requires understanding how each technology behaves under aviation-grade conditions.

What Defines a Flight-Critical Display Environment?

A flight-critical display environment refers to avionics and aerospace systems where interface performance supports navigation, monitoring, and system control. These displays operate continuously and often remain in service for decades.

Display design services must consider key environmental characteristics such as:

- Continuous vibration and mechanical stress

- Wide operating temperature ranges

- High reliability and redundancy requirements

- Strict certification and validation standards

- Long product lifecycle expectations

Touchscreen technologies must maintain consistent input recognition without recalibration drift or physical degradation.

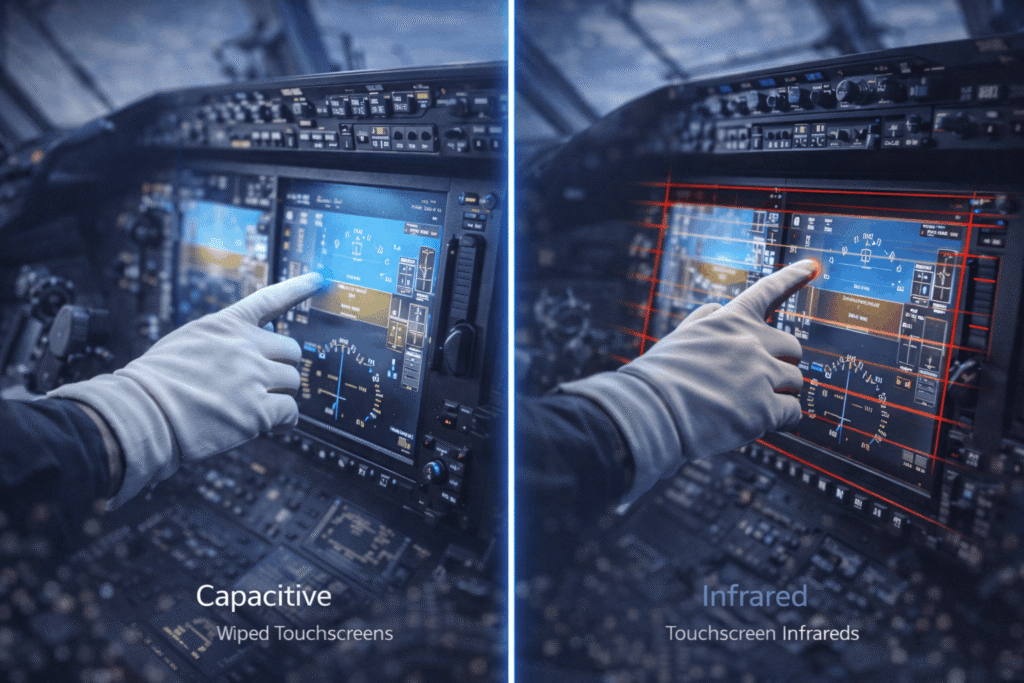

How Capacitive Touchscreens Work

Capacitive touchscreens detect input through changes in an electrostatic field across a conductive surface. A transparent conductive layer embedded in glass detects touch when a conductive object changes capacitance.

In flight-critical displays, projected capacitive designs allow sensing through thicker cover glass. This construction improves durability while preserving accuracy.

Key characteristics of capacitive touchscreens include:

- High positional accuracy

- Multi-touch capability

- Solid glass surface construction

- Minimal moving components

Capacitive systems maintain consistent performance over millions of activation cycles.

How Infrared Touchscreens Work

Infrared touchscreens use an array of emitters and detectors positioned along the display perimeter. These components create an invisible grid of infrared light beams across the surface.

When an object interrupts the light path, the system calculates the touch position from the resulting beam interruption patterns.

Infrared touchscreens offer:

- No overlay on the display surface

- Operation with gloves or passive tools

- High optical clarity

However, infrared systems in custom display designs rely on precise emitter and detector alignment and unobstructed light paths.

Performance Comparison in Flight-Critical Display Environments

In aviation environments, performance consistency outweighs interface flexibility.

Capacitive touchscreens deliver stable accuracy under vibration because sensing layers remain embedded and sealed. Glass construction resists wear and environmental exposure.

Infrared touchscreens may experience performance variability when contaminants, condensation, or mechanical misalignment affect the beam path. Vibration and debris accumulation increase maintenance sensitivity.

Capacitive systems support compact form factors and sealed enclosures. Infrared systems require additional bezel space for optical components.

Failure Modes and Risk Considerations

Failure behavior matters as much as normal operation in flight-critical systems.

Capacitive touchscreen failure modes typically involve gradual sensitivity reduction or controller degradation. Such changes in displays with custom LCD designs occur predictably, and they are easier to detect during maintenance cycles.

Infrared touchscreen risks include

- False inputs from environmental obstructions

- Reduced accuracy if emitters degrade

- Sensitivity to dust, moisture, or surface contamination

In environments with uncontrolled variables, fewer exposed components reduce operational risk.

Which Touch Technology Is Better Suited for Flight-Critical Displays?

Selecting between capacitive and infrared touchscreens for flight-critical display environments requires careful evaluation of reliability, failure behavior, and environmental tolerance.

Capacitive touchscreens are commonly selected for flight-critical requirements due to sealed construction, long-term stability, and predictable behavior under stress.

Infrared touchscreens remain useful in non-sealed or industrial settings where glove compatibility outweighs enclosure constraints. However, their exposed optical paths introduce variables that complicate certification and long-term reliability planning.

For aerospace and avionics applications, capacitive touchscreens typically align better with lifecycle expectations and safety-driven design standards. Capacitive technology provides structural durability and consistent input accuracy under demanding aerospace conditions.

Custom display design services for mission-critical applications often involve collaboration between display engineers and OEM teams. Contact E3 Displays for touchscreen integration planning aligned with long-term operational and certification requirements.